Welcome Chiya Electric Technology Co.,ltd.

CN

CN

Welcome Chiya Electric Technology Co.,ltd.

CN

CN

KYN28-12 Armoured removable enclosed switchgear is suitable for three-phase AC rated voltage of 12kV and rated frequency of 50Hz power system, which is used to receive and distribute electrical energy and control, protect and monitor the circuit.

Tel:+86-0577-62700022

MessagesProduct Introduction

KYN28-12 Armoured removable enclosed switchgear is suitable for three-phase AC rated voltage of 12kV and rated frequency of 50Hz power system, which is used to receive and distribute electrical energy and control, protect and monitor the circuit.

Standards:

GB3906-2006 "3.6~40.5kV AC Metal-enclosed Switchgear and Control Equipment"

GB11022-89 General Technical Conditions for High Voltage Switchgear

IEC298 (1990) "AC metal-enclosed switchgear and control equipment with rated voltage above 1kV and below 50kV and below"

DL404-97 "Technical Conditions for Ordering Indoor AC High Voltage Switchgear"

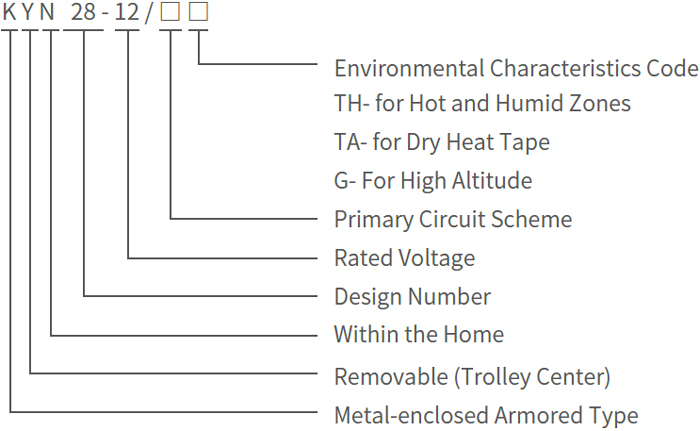

Model Meaning

Functions and Features

The switchgear is designed according to the armored metal-enclosed switchgear in GB3906-91. The whole is composed of two parts: the cabinet and the central extractable parts (i.e. the handcart). The cabinet is divided into four separate compartments with IP4X enclosure protection and IP2X rating for each compartment and the circuit breaker room door when opened. It has overhead inlet and outlet lines, cable inlet and outlet lines and other functional schemes, and forms a complete set of power distribution system devices after arrangement and combination. The switchgear can be installed, commissioned, and maintained from the front, so it can be mounted back-to-back, in a double arrangement, and against a wall, increasing the safety, flexibility and footprint of the switchgear.

◇ Enclosure and others

The main cabinet frame of the switchgear is made of aluminum-zinc thin steel plate, processed by CNC machine tools, and adopts multiple folding process, so that the whole cabinet not only has high precision, strong anti-corrosion and anti-oxidation effect, but also makes the cabinet lighter than other similar equipment cabinets as a whole, high mechanical strength and beautiful appearance due to the use of multiple folding process. The cabinet body adopts an assembled structure, which is connected by rivet nuts and high-strength bolts, so that the processing cycle is short, the parts are versatile, the floor space is small, and it is convenient to organize production.

◇ Hand car

The handcar skeleton is assembled from thin steel plates that are processed by CNC machine tools. The handcart and the cabinet are insulated and cooperated, and the mechanism interlocking is safe, reliable and flexible. According to the use, handcarts can be divided into circuit breaker handcarts, voltage transformer handcarts, metering handcarts, isolation handcarts, etc. All kinds of handcars are changed according to the modulus and building blocks, and the handcars of the same specification can be 100% freely interchangeable. The handcart has a disconnected position, a test position and a working position in the cabinet, each position is equipped with a positioning device to ensure that the interlock is reliable, and must be operated according to the interlocking anti-misoperation procedure. When the handcart needs to move away from the cabinet, with a special transfer cart, it can be easily withdrawn to carry out various inspections and maintenance;

◇ compartments

The main electrical components of the switchgear have their own independent compartments, namely: circuit breaker handcar room, bus room, cable room, relay instrument room. Each compartment has an IP2X degree of protection, and except for the relay, the other three compartments have their own pressure relief channels. Due to the central type, the space in the cable room is greatly increased, so that the device can be connected to multiple cables.

a. Circuit breaker compartment

Rails are installed on both sides of isolation, and handcart 15 is provided to move and slide to working position from disconnection position, test position in cabinet. The partition plate 13 (valve) of static contact box 6 is installed behind the rear wall of the handcart chamber. When the handcart moves from the disconnected position and the test position to the working position, the flaps on the upper and lower static contact boxes are linked with the handcart and automatically open at the same time; when the handcart moves in the opposite direction, the flap will automatically close until the handcart retreats to a certain position and covers the static contact box, forming an effective isolation. Since the upper and lower flaps can be operated separately, the flap on the live side can be locked during maintenance, so as to ensure that the maintenance personnel do not touch the live body. When the door of the circuit breaker room is closed, the handcart can also be operated, and through the observation window of the middle door, the handcart in the compartment can be observed, the position of the handcart closed, and the energy storage status can be displayed.

b. Busbar compartment

The main bus 4 is a single splicing through each other. It is fixed by means of a branch bus 2 and a static contact box. The main bus and the contact bus are copper bars with rectangular cross-section, which are assembled by two busbars when used for large current loads. The branch bus is connected to the static contact box 6 and the main bus by bolts, and no other support is required. For the need, the bus bar can be covered with a heat shrinkable sleeve and a connecting bolt insulating sleeve and an end cap, and the adjacent cabinet bus bar is fixed with a sleeve 3. The air buffer retained between the connecting busbars in this way can prevent it from melting if there is an internal fault arc, and the casing 3 can effectively limit the accident in this cabinet and not spread to other cabinets.

c. Cable compartments

The switchgear is centrally mounted, resulting in a large space in the cable room. Current transformer 7, grounding switch 8 are installed on the rear wall of the compartment, and lightning arrester 10 is installed on the lower part of the rear of the compartment. After opening the door under the cabinet, the construction personnel can enter the cabinet from below for installation and maintenance. The cable connection conductor in the cable room can be combined with 1 ~ 3 single-core cables per phase. If necessary, 6 single-core cables can be connected in parallel per phase, and the bottom of the cabinet connecting the cables is equipped with a detachable non-metallic sealing plate or a non-magnetic metal sealing plate with a slit, which is convenient for construction.

d. Relay instrument room

The relay instrument room can be installed with relay protection components, meters, live monitoring indicators, and required secondary equipment. The control line is laid in a trunking with sufficient space and has a metal cover plate to isolate the secondary line from the high-voltage chamber. Its left trunking is reserved for the introduction and introduction of the control small busbar, and the control line inside the switch cabinet itself is laid on the right side, and the small bus crossing hole that is convenient for construction is also left on the top plate of the relay instrument room. When wiring, the top cover of the instrument room can be turned over to facilitate the installation of small busbars.

◇ Prevent misoperation of the interlock device